Overview of Customized Dental Floss Picks

A customized dental floss pick combines two essential oral hygiene tools in a single compact product: a tightly stretched, high-tensile floss segment and a pointed pick or stimulator at the end of the handle. The floss gently cleans plaque and food debris between teeth, while the pick helps dislodge stubborn particles along the gumline or in tight spaces that are difficult to reach with a toothbrush alone. When you add branding, tailored packaging and bespoke specifications, this everyday oral care accessory becomes a highly visible promotional product, a professional dental clinic giveaway or a consistent private-label retail item that reinforces your brand every time it is used.Why Dental Floss Picks Matter in Modern Oral Care

In many markets, consumers find traditional string floss inconvenient or difficult to manipulate, especially for back teeth or for people with reduced dexterity. A floss pick solves this by providing a pre-tensioned length of floss on a firm, ergonomic handle, making the motion more intuitive and less time-consuming. For clinics and brands, this means higher acceptance and more frequent use, which directly supports better oral hygiene outcomes and increases the perceived value of your product or service. By offering customized dental floss picks, you are not just handing out a generic hygiene item; you are providing a thoughtfully designed tool that encourages regular flossing in a user-friendly format.Dual Function: Floss and Pick in One

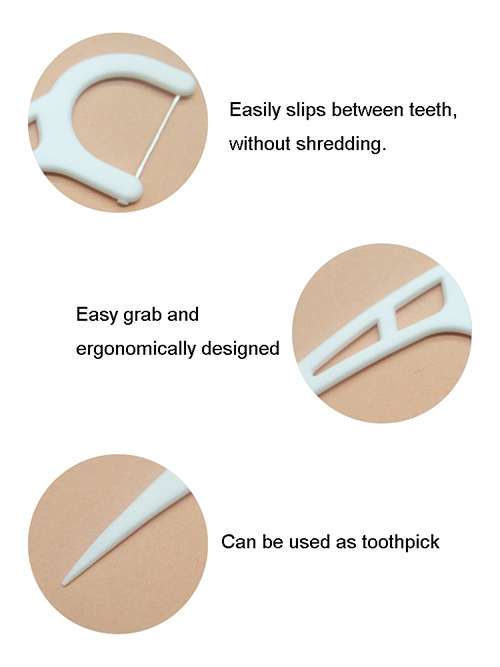

The defining characteristic of a dental floss pick is its dual function. On one side, the floss section glides between teeth to disrupt plaque biofilm and remove food residues where toothbrush bristles cannot reach. On the other side, the tapered pick can be used to gently trace along interdental spaces and the gumline, offering targeted cleaning in narrow gaps. In many of our standard and customized models, the pick portion is shaped with a subtle arc, allowing users to approach difficult angles comfortably while maintaining control. This two-in-one structure makes it an ideal product for travel kits, hospitality amenities, clinic starter packs and branded promotions.User-Friendly Design for Daily Use

A core design principle of our customized floss picks is ease of use. The handles are carefully contoured for a stable grip, providing enough surface area for fingers to hold firmly even when wet, while remaining compact enough to store in a small plastic case, travel pouch or paper sachet. The floss itself is selected for its combination of strength, smoothness and flexibility, reducing the risk of breakage or shredding in tight contacts. When you opt for custom floss picks through our factory, you can specify floss thickness, material and flavor profile to match your target demographic and market preferences, ensuring a comfortable daily experience for users across different age groups and oral conditions.Key Features and Technical Specifications

As a specialized oral care products producer in Hong Kong and China, we pay close attention to both functional features and regulatory requirements. From floss materials and handle polymers to flavoring agents and packaging formats, every aspect of our customized floss picks is adjustable within the framework of international quality and safety standards. Below is a general overview of the common technical characteristics we offer; specific configurations can be tailored to your project needs.Floss Material and Performance

The heart of a floss pick is the floss itself. We typically offer options such as high molecular weight polyethylene fiber or similarly durable synthetic filaments, chosen for their excellent tensile strength, elasticity and resistance to fraying. The goal is to create a floss strand that holds tension even when pressed into very tight interdental spaces, while remaining gentle on gingival tissues. For more premium private-label lines, we can explore variants such as ultra-smooth monofilament floss, expanded filament types that increase contact surface area or waxed versus unwaxed finishes that affect glide and tactile feedback. We also support flavored coatings like mint or herbal blends to provide a clean, refreshing aftertaste that aligns with your brand positioning.Smooth, Burr-Free Cutting and Stretching

The floss segment is precisely cut and anchored to the handle in a way that ensures smooth edges and consistent tension. A burr-free tip on the floss entry and exit points prevents micro-abrasions or snagging when inserted between teeth. Through our manufacturing processes, we ensure that the floss strands are evenly tensioned across large production runs, giving your customers a consistent, reliable experience from pick to pick, pack to pack.Handle Design and Material Options

The handle of the floss pick is more than just a plastic frame; it is the interface between your brand and the user’s hand. We offer standard ergonomic silhouettes as well as fully custom-molded designs that can be adapted to your brand guidelines or unique functional concepts. Most handles are produced from food-grade polymers, commonly polypropylene (PP) or similar materials, that balance rigidity with a slight flex, providing comfortable leverage without being brittle. The end of the handle often incorporates a gently tapered or arc-shaped toothpick tip for additional interdental cleaning. Depending on the brief, we can also explore eco-conscious materials, tighter tolerances on flexibility, surface texturing for grip and customized color matching to Pantone references.Ergonomic Grip and Stability

Because many users floss in front of a mirror with wet hands or in tight bathroom spaces, grip stability is critical. We can integrate flattened or widened sections, anti-slip textures and subtle curves that align naturally with finger placement. This is particularly important for products targeted at children, older adults or people with reduced hand strength, where the right geometry can make flossing more accessible and less intimidating. An ergonomic grip not only improves user satisfaction but also increases the likelihood that your branded floss pick will become a staple in daily routines.Flavor, Color and Scent Customization

To create distinctive customized dental floss picks, we support multiple sensory customization options. Mint is the most recognized flavor worldwide, but we can also explore mild herbal notes, gentle fruit aromas or neutral, flavor-free variants depending on local regulations and consumer expectations. Handle color is fully customizable, whether you prefer clean white, translucent tints or bold brand colors. For multi-brand or multi-sku programs, we can coordinate colors across different SKU lines to make it easier for customers to differentiate between children’s picks, adult picks, sensitive gum versions or eco-focused ranges.Branding and Customization Options

The main reason brands and distributors come to our Hong Kong and China oral care factory is the depth of customization we can provide, both on the product itself and in the surrounding packaging. From simple logo printing on standard shapes to fully bespoke form factors and multi-language packaging, we design the project around your market strategy and regulatory landscape.Logo Print and Surface Branding

One of the most direct and cost-effective branding options is logo application on the handle or the individual packaging. Depending on the handle shape and material, we can use pad printing, hot stamping or laser marking to place your logo, brand name or regulatory marks in visible but unobtrusive locations. For single-use sachets or small plastic cases, we can apply full-color printed labels or direct printing, enabling more complex visual narratives including taglines, QR codes, promotional messages or simple instructions in multiple languages.Custom Molded Shapes and Signature Designs

For brands that seek maximum differentiation, we offer the possibility of developing custom-mold tooling for the handle shape. This allows you to incorporate unique silhouettes, distinctive cut-outs or special ergonomic features that can become instantly recognizable elements of your product line. Although custom tooling involves a higher initial investment and longer lead times, it can deliver strong brand equity over the long term, especially if the design language aligns with other products in your oral care range, such as toothbrushes, tongue cleaners or interdental brushes that we may also be manufacturing for you.Private Label and OEM / ODM Services

As an international oral care factory and producer, we operate both as an OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer). For OEM projects, we produce according to your existing designs, specifications and compliance documents, ensuring that your current formulations and performance characteristics are respected. For ODM projects, we support you from concept to final product, including mechanical design, material selection, flavor development and packaging design. In both models, we provide transparent communication, detailed documentation and sample approval steps so that your customized dental floss picks are aligned with your brand roadmap and regulatory strategy in your target markets.MOQ, Colorways and Line Extensions

We understand that every market has different volumes and risk profiles, especially when launching new customized oral care products. We therefore work with flexible minimum order quantities (MOQs) tailored to different packaging configurations and distribution channels. Many clients start with a core SKU in a single color and flavor, then gradually extend into new variants once they have validated demand. Because we maintain a broad component and packaging ecosystem, it is straightforward to expand your line into different colorways, flavors or pack sizes without redesigning the entire system from scratch.Packaging Formats for Global Markets

Packaging is a major component of the user experience and an essential element of compliance with regional regulations. Whether your customized dental floss picks are destined for retail shelves, e-commerce warehouses, professional dental clinics or hospitality amenities, we can recommend and supply suitable packaging configurations that align with your budget, sustainability goals and distribution requirements.Standard and Custom Pack Sizes

We commonly produce packs containing anywhere from 10–15 picks for travel or sample kits up to larger family packs with 50, 60 or more floss picks per unit. Smaller packs are excellent for promotional giveaways, hotel amenities or dental clinic starter kits, while larger packs are ideal for retail channels and subscription models. Pack sizes can be harmonized with your existing oral care lines so customers can easily compare value and choose the quantity that fits their lifestyle, whether they are single users, couples or families.Primary Packaging: Cases, Pouches and Sachets

Primary packaging refers to the immediate container that holds the floss picks. We supply a variety of options, such as compact plastic cases with snap-shut lids for portability, resealable pouches that balance convenience with reduced material use or individually wrapped picks in foil or paper sachets for maximum hygiene. Each approach has strengths depending on the intended environment: cases are ideal for daily carry in bags or drawers, pouches are efficient for home storage and individually wrapped units are perfect for clinics, airlines, hotels and on-the-go consumers who prioritize single-use cleanliness.Secondary and Tertiary Packaging for Distribution

Beyond the primary container, we design secondary and tertiary packaging solutions such as printed paper boxes for retail display, shelf-ready trays, transport cartons and export pallets. These layers are engineered for strength and logistics efficiency, protecting your customized floss picks during shipping while meeting labeling and barcoding requirements (including GTIN / EAN, batch codes and expiry or production dates where applicable). For cross-border distribution, we can support multi-language labeling and adapt packaging layouts to meet local legal expectations in Europe, North America, Asia-Pacific and other regions.Sustainability and Material Reduction

Many of our clients are actively working to reduce their environmental footprint while maintaining product safety and performance. We can support initiatives such as reducing plastic thickness in non-critical areas of the handle, exploring bio-based or partially bio-derived polymers where regulations and performance allow, switching from hard plastic cases to flexible pouches or paper boxes and optimizing carton layouts to reduce shipping volume. We work collaboratively with each client to find a practical balance between eco-conscious design and the realities of manufacturing, transport and end-of-life disposal in different markets.Quality Assurance and Regulatory Compliance

Because oral care products come into contact with sensitive oral tissues every day, quality control is not optionalit is fundamental. Our dental floss picks are produced under controlled manufacturing conditions with established quality management systems designed to support compliance in demanding regulatory environments. As a producer serving international brands, we are familiar with the documentation and audit expectations associated with importing and selling oral care accessories across diverse markets.Material Safety and Traceability

All materials used in our customized dental floss picks, from floss filaments and polymer handles to flavoring components and inks, are selected from qualified suppliers with appropriate safety and compliance documentation. We maintain batch records and traceability so that every finished product can be linked back to specific raw material lots and process parameters. This traceability is crucial for efficient quality investigations, continuous improvement and alignment with client requirements for audits, supplier qualification processes and internal quality reporting.Process Controls and Product Testing

During production, we implement process controls such as monitoring floss tension, handle integrity, bonding strength between floss and frame, dimensional conformity and visual inspection for defects. Periodic testing may include floss tensile testing, color and odor consistency evaluations and checks on packaging seal integrity to ensure that product quality is maintained throughout storage and shipping. Clients may also request custom test protocols and acceptance criteria to reflect their brand standards or local regulations.International Standards and Customer Requirements

Different markets may reference different norms or guidelines for oral care accessories, including general consumer safety directives, plastic contact material regulations and flavoring limitations. We collaborate with clients to understand the framework that applies to their product and integrate those requirements into our production and documentation systems. This can include material declarations, certificates of analysis, safety data from ingredient suppliers and packaging specifications that support regulatory submissions or retailer onboarding processes.Applications and Use Cases

Customized dental floss picks produced in our Hong Kong and China factory are used by a wide variety of partners worldwide. From small dental clinics to global retail brands, the versatility of this product means it can be positioned in numerous ways to support your commercial and educational objectives.Retail and E-commerce Brands

For consumer-facing brands, floss picks can be offered as standalone SKUs, combined with toothbrushes in bundled hygiene kits or integrated into wider product lines that include mouthwash, toothpaste and interdental brushes. Because they are lightweight and relatively compact, they ship efficiently for e-commerce, making them suitable for subscription models and online retail. Custom branding and high-quality photography on packaging also make the product visually appealing on digital platforms, where detail shots of floss texture, handle shape and case design can influence purchasing decisions.Dental Clinics and Professional Practices

Dentists and hygienists around the world use customized dental floss picks as educational tools and patient take-home items. By printing the clinic logo and contact details on the packaging, practitioners can reinforce their brand while encouraging patients to follow prescribed home-care routines. Picks are generally easier to demonstrate than traditional floss in a chairside setting, particularly for children or people who have never flossed regularly before. Our factory can produce clinic-branded picks in cost-effective quantities, packaged in small pouches or boxes ideal for handing out after check-ups or periodontal treatments.Corporate, Hospitality and Travel Programs

Hotels, airlines, cruise lines and corporate wellness programs often include oral care items in amenity kits and welcome packs. Customized floss picks are an excellent addition to these sets, as they are compact, hygienic and perceived as a thoughtful detail. We can supply individually wrapped picks or mini-cases carrying your corporate logo and subtle messaging, matching the visual identity of existing amenities. For travel or hospitality use, we place particular emphasis on tamper-evident packaging and clear usage instructions in multiple languages, helping guests feel confident about using the product even far from home.How to Use Customized Dental Floss Picks

Although floss picks are intuitive, clear instructions can help users obtain the maximum benefit and avoid discomfort, especially if they are new to flossing. Many brands choose to print simplified instructions directly on the packaging or include an illustrated leaflet in multi-pack boxes. When developing customized floss picks with us, we can assist with creating and localizing these instructions so they are both accurate and culturally appropriate.Step-by-Step Flossing Guidance

To use a dental floss pick effectively, the user should guide the floss gently between two teeth using a subtle back-and-forth motion to pass the contact point, then curve the floss around the side of one tooth in a “C” shape to clean below the gumline with several up-and-down strokes. The process is then repeated on the adjacent tooth surface before moving on to the next gap. The pick end can be used afterward to loosen any remaining particles or reach narrow spaces where the floss may not pass easily. Advising users to follow a systematic routinestarting from the back teeth on one side and moving along to the otherhelps ensure that no area is overlooked.Hygiene and Safe Handling

Because floss picks are typically single-use items, users should be advised to discard each pick after one full mouth cleaning session. Reusing picks can reduce performance and introduce microbial contamination. Packaging should also clearly indicate that the product is not a toy and should be used under adult supervision for younger children. For children or people with sensitive gums, it is important to emphasize a gentle technique, avoiding aggressive sawing motions that could harm soft tissues. On request, we can adapt the floss type and handle design to better suit sensitive users or specific clinical recommendations, making your customized picks safer and more appealing across diverse user groups.Manufacturing in Hong Kong and China: Advantages for Global Clients

Our location and operational structure provide distinct advantages for international brands and distributors seeking customized dental floss picks and other oral care products. As an established factory in Hong Kong and China, we combine regional manufacturing expertise with export-oriented logistics and multilingual customer support, creating a streamlined experience from initial briefing to final shipment.Efficient Production and Competitive Pricing

By leveraging regional supply chains and scalable manufacturing infrastructure, we can deliver high-quality customized floss picks at competitive unit costs, even for complex or highly branded configurations. Our teams are accustomed to working with both high-volume retail-oriented orders and more specialized, lower-volume runs for clinics, hospitality projects and targeted promotions. This flexibility allows us to structure pricing and production schedules around your business model, whether you require consistent, recurring shipments or one-off campaigns timed to specific marketing events.Export Logistics and Support

Exporting oral care products requires attention to documentation, labeling, shipping regulations and sometimes certification processes in destination markets. We support our clients with the necessary shipping documents, product specifications and, where relevant, cooperation with local importers or distributors on regulatory filings. Our logistics partners have extensive experience handling both sea and air freight for consumer goods, enabling us to recommend transport solutions that balance speed, cost and environmental impact according to your priorities.Sample Development and Project Workflow

To ensure that your customized dental floss pick meets expectations, we follow a structured development process beginning with consultation, followed by design and sampling, then trial production and full-scale manufacturing. Clear communication at each step helps minimize surprises and allows refinements before final approval.Initial Consultation and Specification

At the outset, we work with you to define key parameters: target market and application, desired floss characteristics, handle shape, color palette, branding elements, pack sizes, packaging types and any regulatory constraints. If you already have a technical specification or incumbent sample, we analyze those details to ensure compatibility. If you are starting from a concept, we can propose a range of feasible options and help you choose the best configuration based on your budget, timeline and positioning goals.Prototyping and Sample Approval

Once the project outline is agreed, we produce physical samples for your review. These initial samples allow you to evaluate floss performance, handle ergonomics, coloring and flavor intensity, as well as visual elements on packaging. Feedback from your teamsometimes including internal dental professionals or external key opinion leadersthen guides revisions. This iterative loop continues until you are satisfied, after which we lock the specifications for mass production. For complex designs or custom molds, we may also provide pre-production validation samples from early tooling runs.Scale-Up and Long-Term Collaboration

After sample approval, we move into volume manufacturing according to an agreed production and shipping schedule. For ongoing partnerships, we often coordinate forecasts and call-off plans in advance so that lead times and inventory levels are optimized for your sales cycles. Our aim is to become a long-term extension of your team, providing not only customized dental floss picks but also a platform for expanding your oral care range as your brand grows in different regions and channels.Frequently Asked Questions About Customized Dental Floss Picks

The following FAQ section, marked up with structured data-friendly attributes, addresses common questions we receive from international clients about our customized dental floss pick products, manufacturing and service capabilities.Can we fully customize the design and branding of the dental floss pick?

Yes, we offer extensive customization options for both the floss pick and its packaging. You can choose handle colors, floss type and flavor, pack sizes, logo placement and multi-language packaging designs. For brands seeking maximum differentiation, we can also develop custom-molded handle shapes as part of an OEM or ODM project, creating a unique signature design that aligns with your wider oral care portfolio.

What minimum order quantities (MOQs) apply to customized dental floss picks?

MOQs depend on factors such as handle design, color combinations, floss specifications and packaging formats. Standard designs with common colors and pack sizes typically have lower MOQs, making them suitable for clinics, regional brands or pilot programs. Fully customized molds, complex printing layouts or special materials may require higher MOQs to remain cost-effective. During the initial consultation, we provide clear MOQ guidelines for each configuration so you can plan your product launch with confidence.

Can you support international regulatory and documentation requirements?

We regularly work with international clients who distribute oral care products across Europe, North America, Asia-Pacific and other regions, and we understand that documentation and compliance are essential. We can provide material declarations, specifications, batch traceability information and other supporting documents typically required by importers, retailers and regulatory authorities. We also collaborate with your regulatory or quality teams to align formulations, labeling and claims with the applicable rules in your destination markets.

Do you offer eco-friendly or reduced-plastic options for floss picks?

We actively support sustainability-oriented projects and can explore multiple strategies to reduce environmental impact. These include optimizing handle geometry to use less plastic, introducing alternative or partially bio-based polymers where suitable, switching from rigid cases to lighter pouches or paper boxes and designing packaging systems that minimize shipping volume. While technical and regulatory constraints may limit certain materials for oral contact, we work closely with you to find practical, responsible solutions that reflect your brand’s sustainability commitments.

What is the typical lead time for development and mass production?

Lead times vary based on project complexity. For standard floss pick designs with custom branding and packaging, development and sampling can often be completed in a relatively short timeframe, followed by an agreed production window depending on volume. Custom-molded handles or special materials add additional development time for tooling and validation. During the project planning phase, we provide an indicative schedule covering design, sampling, approval, production and shipping so that your launch timings can be aligned with marketing or seasonal campaigns.

Can we order samples before placing a bulk order?

Yes, we strongly recommend and provide samples prior to bulk production. Sample evaluation allows you to test floss performance, handle ergonomics, color accuracy, flavor intensity and packaging quality. You can share these samples internally with your product, marketing and dental professional teams, and we can then adjust the specifications based on their feedback before moving to full-scale manufacture. This approach helps ensure that the final customized dental floss pick meets your expectations in both function and brand presentation.

Are these customized floss picks suitable for children and sensitive users?

We can tailor floss picks to different user groups, including children and people with sensitive gums. This may involve using a slightly softer or thinner floss variant, selecting milder flavors and designing smaller or rounded handles that are easier for small hands to control. Clear safety instructions and age recommendations can be included on the packaging. For pediatric or sensitive-care projects, we encourage collaboration with dental professionals in your network so that our technical team can align product design with clinical advice.

How are the customized dental floss picks packaged for shipping and storage?

The shipping configuration is designed to protect your customized floss picks while making handling efficient and cost-effective. Depending on your chosen primary packagingsuch as plastic cases, resealable pouches or individually wrapped pickswe place units into printed retail boxes or bulk cartons, which are then stacked on pallets for sea or air freight. Cartons are labeled with key identifiers like product codes, batch numbers and destination details, simplifying warehouse operations and helping maintain traceability from factory to final point of sale or use.